Updated 21 June 2025 at 11:55 IST

What is a Rare Earth Magnet and How Is It Impacting The Indian Automotive Industry

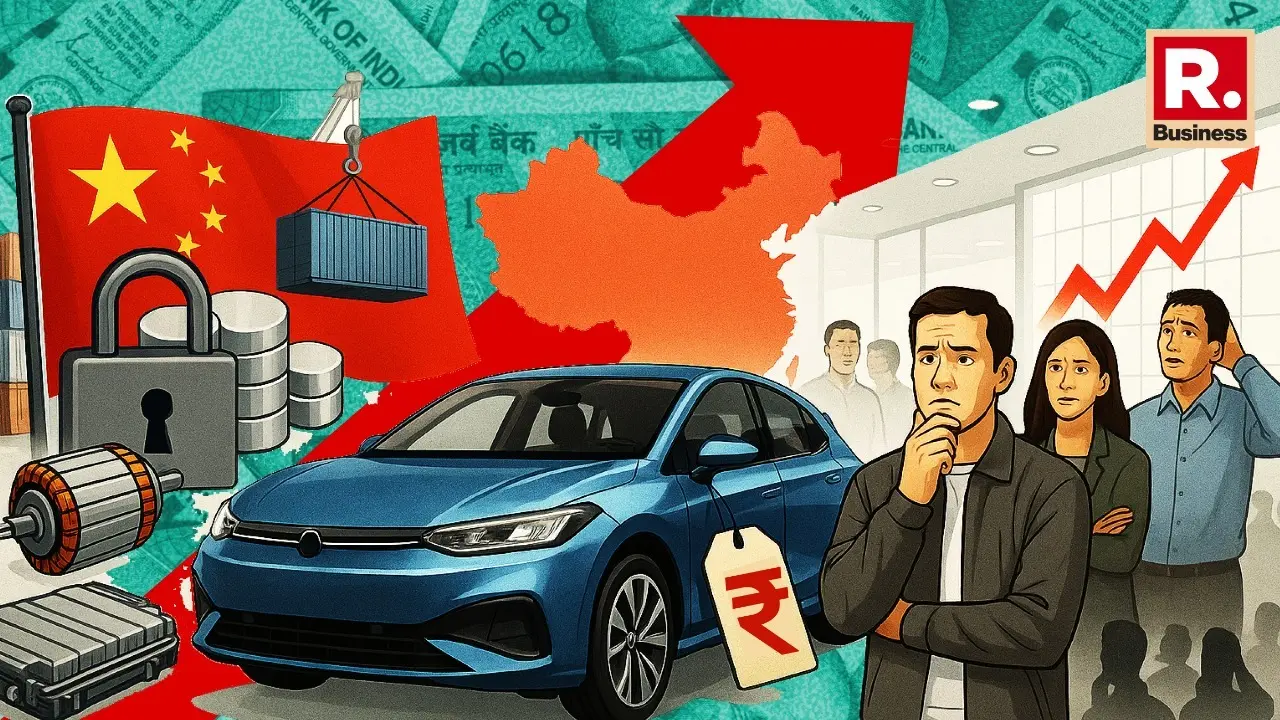

India, which imported more than 80% of its 540-ton magnet imports from China during the previous fiscal year, is witnessing a supply crisis. Above all, the prices of rare earth materials often spike due to trade tensions or export restrictions. For an EV market that is still price-sensitive, this is a big concern.

- Republic Business

- 2 min read

Even while you may not be able to see them, rare earth magnets are inside many devices you use every day — from headphones and smartphones to wind turbines and electric cars. These elements are now becoming essential to India’s automotive future, especially as the country shifts towards electric mobility.

What Are Rare Earth Magnets?

Rare earth magnets are a type of strong permanent magnet made from alloys of rare earth elements, primarily from the lanthanide series. They are made using a group of 17 chemically similar elements found in the Earth’s crust, mainly neodymium and samarium. While they are not actually rare, extracting and processing them is expensive and complicated.

Also Read: China Rare Earth Magnet Restriction Threatens India EV Boom, Warns Crisil | Republic World

Where Are They Used?

In passenger vehicles, rare earth magnets are used in:

Advertisement

- Electric motors (particularly in EVs and hybrids)

- Power steering systems

- Braking systems

- Speedometers

- Automatic transmission kits

- Cooling fans

- Ignition coils

- Speakers, Sensors, and other electronics

They are also critical elements in other industries — from wind energy to consumer electronics and medical equipment.

What’s Causing the Supply Shortage?

China, which dominates over 90% of the global rare earth supply chain, in April 2025 tightened export controls on rare earth magnet technologies, citing national security concerns. The new framework requires export permits and end-use statements, particularly prohibiting use in defense or re-export to the US. While it is not a blanket ban, the move has disrupted the automotive supply chain of many countries, including India.

Shipments have been greatly delayed by at least 45 days with authorization.

Advertisement

Why They Matter to India’s Auto Sector

For Indian automakers, this adds uncertainty around pricing and access to key components, especially as demand for electric vehicles continues to rise. Most EV motors depend on rare earth magnets to deliver efficiency and torque in a compact design.

India, which imported more than 80% of its 540-ton magnet imports from China during the previous fiscal year, is witnessing a supply crisis. Above all, the prices of rare earth materials often spike due to trade tensions or export restrictions. For an EV market that is still price-sensitive, this is a big concern.

What Measures Could India Take?

To reduce its reliance on Chinese imports, India is:

- Exploring domestic mining through firms like IREL

- Funding R&D through institutions like IITs and DRDO

- Encouraging joint ventures for magnet production

- Exploring the feasibility of Production Linked Incentive (PLI) schemes

- Looking into alternative motor technologies that use fewer or no rare earths

Published By : Avishek Banerjee

Published On: 21 June 2025 at 11:55 IST